THERMANCY

Thermodynamic Pump Efficiency Monitoring

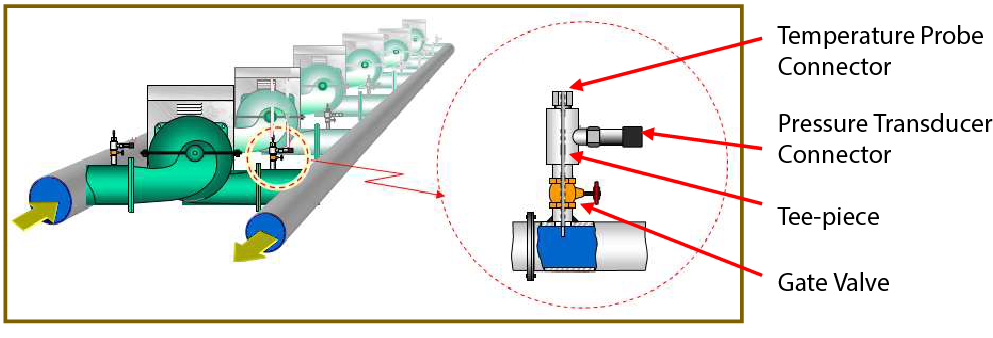

Thermodynamic Pump Efficiency Monitoring measures and monitors a pump's efficiency by analyzing fluid thermodynamic properties. It allows operators to measure key parameters at multiple points in the system and use thermodynamic principles to calculate efficiency. This data detects inefficiencies and potential issues, enabling proactive maintenance and reduced downtime. The technology also optimizes maintenance intervals and lowers energy consumption, resulting in significant cost savings.

- Inefficient energy usage by pumps results in high energy costs

- Unplanned downtime caused by pump failures or malfunctions

- Difficulty in identifying and diagnosing pump issues before they become critical

- Inability to accurately predict pump maintenance needs

- Continuous monitoring of pump efficiency, identifying areas of inefficiency, and allowing for targeted optimization efforts

- Early warning system for pump failures or malfunctions, allowing for proactive maintenance and preventing costly downtime

- Real-time diagnostics and analysis of pump performance, providing valuable insights for maintenance teams

- Accurate predictions of pump maintenance needs, ensuring timely and efficient maintenance schedules

The Benefits

Oil and Gas

Chemicals and Petrochemicals

Water and Wastewater

Manufacturing

Power Generation

Mining and Minerals

Take control of your pumping systems with our Thermodynamic Pump Efficiency Monitoring technology today!

We are committed to offering the highest quality water treatment solutions and strive to be a one-stop center for all industrial water treatment projects and services.

Contact

CDS ENGINEERING SDN. BHD.

(Company No.: 660071-M)(GST No : 000237780992)

24 Jalan Anggerik Vanilla Z31/Z, Seksyen 31, Kota Kemuning, 40460 Shah Alam, Selangor, Malaysia

Tel: +6012 207 6337

Email: enquiries.cdseng@gmail.com

Navigation

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed